- Mobile: +86 13922512395

- E-mail: [email protected]

Tin-antimony alloy solder has excellent weldability and wettability, high welding strength, and high reliability. It is often used in specific packaging processes.

The following uses Sn90Sb10 as an example for introduction.

Material | solidus (°C) | liquidus (°C) | Welding temperature (°C) | density (g/cm3) | Tensile Strength (MPa) | Thermal conductivity (w/m×°C) | Thermal expansion coefficient (×10-6/°C) |

Sn90Sb10 | 240 | 250 | 282 | 8.41 | 44 | 42 | 27 |

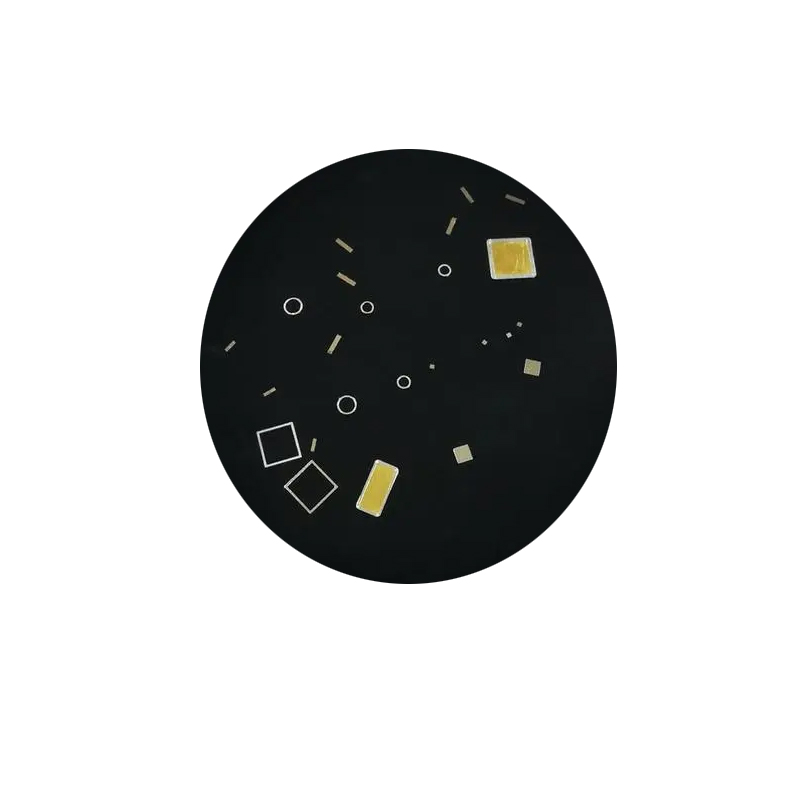

Berlin Materials can provide customers with different shapes of tin-antimony welding strips, welding wires and preformed welding sheets (washers, discs, rings, rectangles and various special shapes as well as various SMD standard welding sheets such as 0402, 0603, 0805, 1206, 1210 etc. piece). Taking Sn90Sb10 as an example, the product parameters are as follows:

Sn90Sb10 solder preform parameters | |

Sn90Sb10 impurity level | <0.1% (mass ratio) |

Solidus/Liquidus Melting Point Shift | +/-1°C |

Minimum thickness of welding ribbon | 0.01mm+/-0.005mm |

Solder preform minimum tolerance | 0.005mm |

Sn90Sb10 solder preform storage and packaging | |

storage temperature | 25+-3°C |

Storage humidity | <40RH |

package style | Can be packaged according to customer requirements |

Sn90Sb10 preform solder sheet welding process parameters | |

Welding protection method | It is necessary to add flux, or use reducing atmosphere or vacuum protection welding |

pre-heat temperature | >120°C |

Preheat time | >10s |

Welding temperature | >282°C |

Welding time | >5s |